Details

:

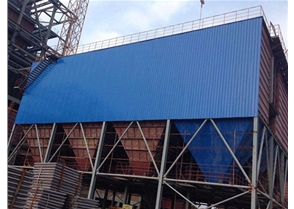

Glass fiber bag filter can operate for a long time under the condition of high dust concentration below 260℃, and the dust collection efficiency can be stable above 99.9%. There are two kinds of positive and negative pressure, automatic bag shrinking and ash cleaning, and equipped with microprocessor control device. It can be fixed time and fixed resistance, and can be repaired without stopping the machine without affecting the production. CXS glass fiber bag dust collector is widely used in cement, electric power, metallurgy, carbon black and other industrial waste gas purification.

Glass fiber bag filter, dry dust filter device. Bag filter is one. It applies to. Glass fiber bag dust collector adopts microcomputer control, chamber back blowing, timing and resistance cleaning, temperature detection and display, so that the glass fiber bag dust collector can run statically in the mechanical shaft kiln waste gas dust removal.

The structure

The basic structure of glass fiber bag filter consists of three parts.

(1) the intake, exhaust and back blowing system of the glass fiber bag dust collector: including the intake pipe, the intake chamber, the back blowing valve, the back blowing duct, the three way pipe, the exhaust valve, the exhaust pipe.

(2) The bag chamber structure of the glass fiber bag filter: including the dust hopper, the maintenance door, the body frame, the upper and lower flower plate, the filter bag and the bag chamber.

(3) Ash discharge system of glass fiber bag dust collector: including ash discharge valve and screw conveyor.

Product features

1. Strong adaptability. It can operate effectively under high temperature (260℃, instant 280℃), high dust (100 g/Nm3), high temperature (dew point 60℃) working conditions.

2, dust collection efficiency of more than 99.9%, emission concentration < 50 mg/Nm3, do smokeless and dust-free, to ensure that the standard.

3. Thoughtful design and reasonable structure. Maintenance can be carried out without downtime without affecting production.

4, with long bag back blowing cleaning technology, anti-condensation structure design, automatic temperature control system, filter bag long service life.

5, reliable use of equipment, simple operation, low operation cost.